-

Product Center

-

home

-

News Center

-

technology

-

download

-

Contact Us

1.1 Introduction

The integrated steel bar scanner is mainly used for testing the position, protective layer thickness, spacing, and diameter of steel bars inside concrete structures, and can accurately draw the distribution map of the overall steel bars, providing accurate and high-speed detection data; Adopting an integrated structure of the host and sensor coil, it is convenient and fast to carry and operate on site; Adopting a multi coil structure design, it has faster speed, higher accuracy, and stronger resolution.

1.2 Functional Features

1.2.1 Main functions

1. Accurately measure the thickness of the protective layer of the steel reinforcement;

2. Determine the position, direction, and distribution of steel bars;

3. Measure the protective layer of the steel bars and estimate the diameter of the steel bars;

4. Storage, viewing, and transmission of detection data.

1.2.2 Features

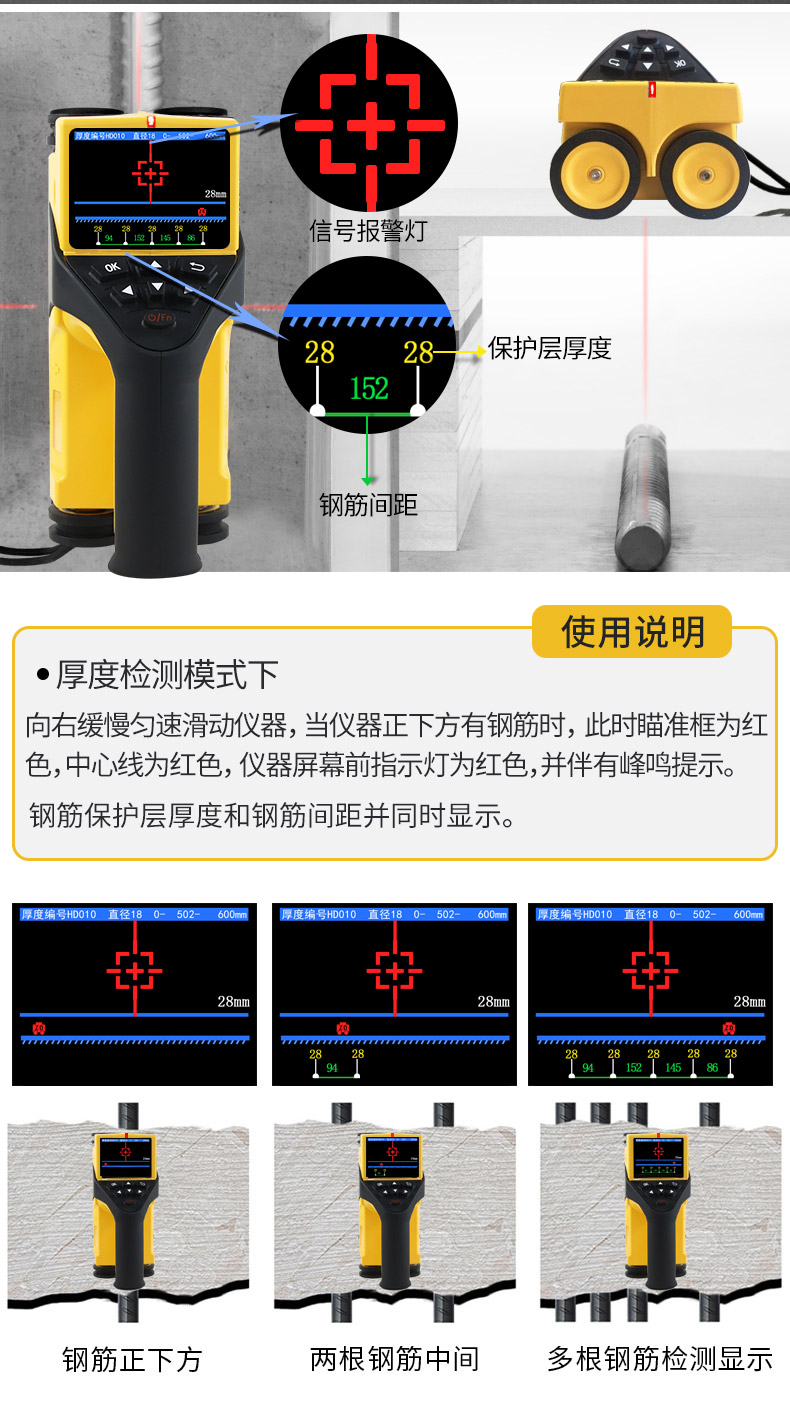

1. The detection mode is intuitive, accurately displaying the position, spacing, and protective layer thickness of the steel bars on the same display screen;

2. Single point measurement, grid scanning, waveform scanning, and profile scanning all fully achieve backward deletion of erroneous test data and graphics, making it convenient for on-site testing and use;

3. During the grid scanning testing process, it is fully possible to switch between the X axis and Y axis (i.e. the vertical and horizontal coordinate axis direction) at any time. After arbitrary switching, the data and steel bar distribution map will automatically continue the previous information for testing, thereby improving the flexibility of on-site testing;

4. Adopting a single hand grip machine, operating design, and four-wheel positioning method, equipped with high-strength wear-resistant tires, easy to protect the instrument from wear and tear;

5. Adopting automatic storage of calibration values to achieve fast measurement and reduce the hassle of each calibration work before detection.

1.2.3 Main Features

1. 2.8 inch high-resolution color LCD screen (320 × 240 pixels), can clearly see the detection data regardless of indoor or outdoor conditions;

2. Multi coil structure design, faster speed, higher accuracy, and stronger resolution;

3. Using USB mode for data transmission and charging, the stored data can be quickly uploaded to the computer through a USB cable;

4. Equipped with a built-in large capacity lithium battery, designed with low power consumption, it can standby normally for about 16 hours when the battery is fully charged;

5. In the data management mode, functions such as data storage, viewing, and deletion can store around 200000 steel bar measurement point data;

6. Adopting the ability to distinguish ultra dense steel bars to solve the problem of steel bar misjudgment;

7. Professional and uniquely designed standard calibration blocks can be configured;

8. Adopting an integrated design of the host and sensor coil, it is compact, lightweight, and easy to carry;

9. Real time judgment of the middle position of adjacent steel bars, with indicator lights indicating that it can avoid surrounding steel bars and facilitate drilling and coring;

10. The protective lining of the instrument box adopts the domestically pioneered ladder and cylindrical guide groove, which is convenient for placing the instrument;

11. Equipped with steel bar detection software, it is convenient for professional data analysis, data processing, and generating complete reports on a PC.

1.3 主要技术指标

表1.1主要技术指标

| 项目 | 指标 |

| 钢筋适用范围(mm) | φ6~φ50 |

| 保护层厚度范围(mm) | 小量程:1~80;大量程:5~185 |

| 显示屏 | 320×240 |

| 供电方式 | 内置高容量锂电池 |

| 工作时间 | ≥16h |

| 通信模式 | USB传输接口 |

| 存储容量 | 20万钢筋测点 |

| 操作方式 | 硅胶按键 |

| 整机体积(mm) | 219×92×106 |

| 整机重量(Kg) | 0.60(内含锂电池) |

表1.2 不同钢筋直径的量程范围

| 量程 钢筋直径(mm) | 小量程(mm) | 大量程(mm) |

| φ6~Φ8 | 1~60 | 5~100 |

| Φ10~Φ18 | 1~80 | 5~120 |

| Φ20~Φ28 | 1~80 | 5~140 |

| Φ32~Φ50 | 1~80 | 5~185 |

表1.3 不同厚度误差范围

| 量程 误差范围 | 小量程(mm) | 大量程(mm) |

| ±1 | 1~59 | 5~59 |

| ±2 | 60~80 | 60~79 |

| ±3 | …… | 80~99 |

| ±4 | 100~185 |