-

Product Center

-

home

-

News Center

-

technology

-

download

-

Contact Us

1、 Purpose

XHZY selective pressure method masonry mortar compressive strength tester is abbreviated as: selective pressure tester or local pressure tester. It is developed and produced in accordance with the industry standard JGJ/T 234-2011 "Technical Specification for Testing the Compressive Strength of Masonry Mortar by Selective Pressure Method" of the People's Republic of China. It is a specialized instrument for testing the strength of masonry mortar. Its characteristic is that it can be directly tested on site or in a laboratory, without affecting the stress performance of the wall. It has the characteristics of easy detection, convenient operation, and high testing accuracy, and can meet the requirements of on-site quality control of masonry engineering and quality appraisal of old and ancient houses Objective needs for evaluation.

2、 Technical performance parameters

1. Measurement range: 0-5000N

2. Stroke: ≥ 18mm

3. Power supply voltage: 5V

4. Head diameter: 10mm

5. Indication error: 1% of full scale

6. Display resolution: 1N

3、 Structure and characteristics

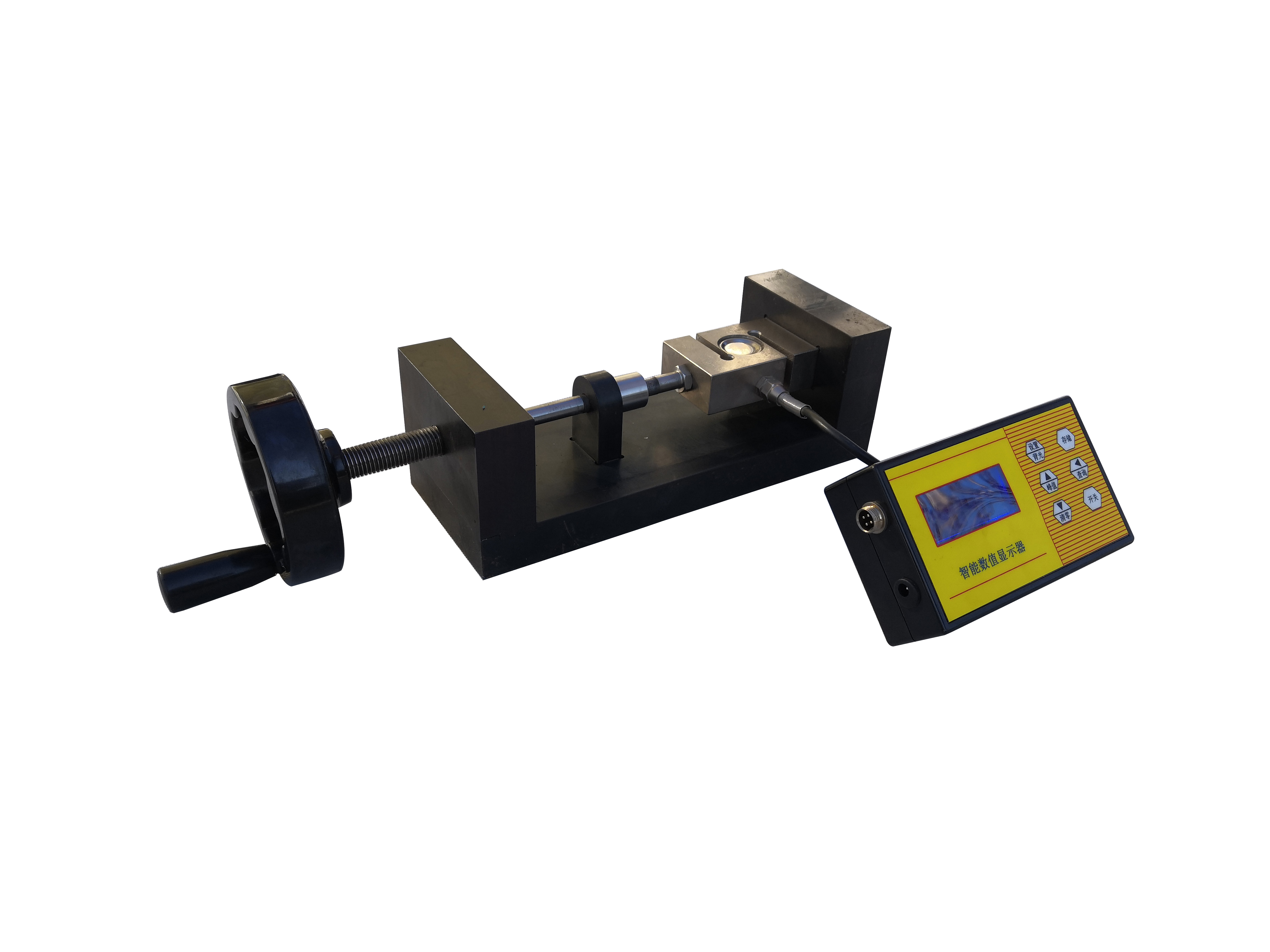

The pressure selector is composed of reaction frame, force measuring system, round flat indenter, middle note device, digital display reading system, loading handle, etc. The sensor is installed on the loading reaction frame, and the digital display reading system and the force sensor are connected with wires.

During work, place the pre taken mortar sample on the pressure head, and slowly rotate the handle of the pressure gauge clockwise by hand to move the lead screw towards the direction of the force sensor. When the loading head holds the mortar sample, a pressure load is generated. Then, slowly and evenly apply the load until the sample breaks. At this time, the intelligent digital pressure display will maintain the maximum load.

4、 Instructions for use

Before using the instrument, connect the connecting wire between the sensor and the intelligent digital pressure display, then turn on the machine and observe if the number on the display is zero. If it is not, press the "Clear" button to reset it.

1. Press the "Peak" button (with the words "Peak" displayed at the top of the screen) to place the test pieces together. At this time, the load can be applied. When the test piece is damaged, the displayed value on the display is the maximum force value of the test piece at this time, in "N". Press the storage button to store the data, or manually record it on the spot.

Note: As the next specimen, it is necessary to reset the instrument and press the "reset" button.

2. Process (or select) large pieces of mortar peeled off at each measuring point into specimens that meet the following requirements: thickness 8-16mm, area not less than 30-30mm, one of which is used as a backup specimen, and the other five are used as test specimens. The two sides of the specimen should be relatively parallel.

3. Mortar samples should be taken within 20mm of the surface, and should not be taken on independent brick columns or walls with a length of less than 1 meter, nor should they be taken on walls directly below load-bearing beams.

4. A thin rubber pad with a thickness of less than 1mm and an area slightly larger than the pressure head should be attached to each of the two circular flat pressure heads of the pressure gauge. When testing, the digital pressure gauge should be set to a peak holding state and the measurement unit should be confirmed to be Newton (N).

5. The mortar specimen should be vertically centered between the two indenters of the pressure gauge, and the distance from the edge of the indenter to the edge of the mortar specimen should not be less than 10mm.

When conducting loading experiments on mortar specimens, the loading rate should be controlled at 1/15-1/10 of the estimated failure load per second, and should continue until the specimen fails. The load value of the pressure gauge should be the peak value displayed on the digital pressure gauge of the pressure gauge when the mortar specimen is damaged.

7. After recording the reading of the intelligent digital pressure display, substitute it into the formula to calculate the intensity, and select the reading unit of the pressure gauge display as N.

Attention: Do not allow the round flat indenter to directly press to avoid damaging the indenter.